This

upgrade is a must for those who like to upgrade performance without

having the expense to play with anything else at all.

Hint: To help you access the ECU screws we suggest to remove

the Air intake hose which maybe in the way. As soon as you remove

the ECU cover I suggest installing a chip base so you can remove

the chip easily any time you want.

This

work can take about 1 hour to complete.

- Will

also give about 210 BHP and a little more torque +5% in low

and midrange

- Gives

very good drivability and is a very good and safe performance

upgrade for all SE/S4

This

chip is based on the improved S4s-Mk5-code but with +5% torque

(and similar top end power)

Is a very good choice like the improved S4s but with that additional

punch in low- and midrange

To help you with managing the ECU and getting a read out of the

errors and you require a program (freescan).You need a serial

cable to connect to you PC as we have. If you're unable to make

the cable please contact us for help.

To

install the chip simply follow the illustrated process on our

mods page

Road test:

The car was found to drive much smoother with noticeable lots

more power in the midrange area. This is a good start for all

stock Esprit's. Running chip #2 gives you more refined running

and extra performance and an all-round better Esprit over the

stock chip. This would also benefit those who run their Esprit's

all year round.

Chip

#2 is available from our parts page.

We

recommend continuing to the second stage to benefit from the ECU

upgrade.

STAGE 2 Air intake and Air box Filter

Parts

used:

- Air

box ram air Modification

- K&N

Filter

- Oil

catch tank

- Chip

#2

Not

all Esprits use the same air ram intake size pipe, depending on

the year of manufacturing as Lotus factored forever made updates

while the vehicle was on the assembly line as to be expected,

lucky enough ours had 100mm intake hoses pipes across the air

assembly. So we only had to cut it a little shorter to rich from

the intake from the body air intake panel directly to the air

box and by past all the unnecessary loops (Usually the factory

directs this hose to an area at the right quarter panel which

causes the fresh air to go for a long trip and back with a another

hose to the air box. This modification can take about 30 minutes

to complete. However if your model has got an inlet smaller then

100mm you just have to make it up with any pipes you can find

or make a mold out of fiberglass.

This

illustrated process is available on our upgrades

page

Note: Be careful not to knock out of place any of the black thin

vacuum pipes especially the one to the map sensor (see pic below)

otherwise you will experience a very bad start to the car with

code 33 error and possibly and "check engine warning light

displaying.

Note

the position of the vacuum hose on the map sensor located under

the right guard

K&N Filter: We managed to score the correct size K&N

filter for the job as I found out they are sometimes hard to get

but now available on our parts list page. This unit should last

for a very long time in fact some people claim possibly for the

life of the car, as the only requirement is cleaning it.

To

get to the filter you need to remove the Air intake hose to the

Turbocharger unit and the 2 x 10mm bolts on both sides of the

Airbox.

Note:

Make sure to use the original rubber seal from the old filter

as the K&N filter does not come with one.

<Original and K&N air filter

<Original and K&N air filter

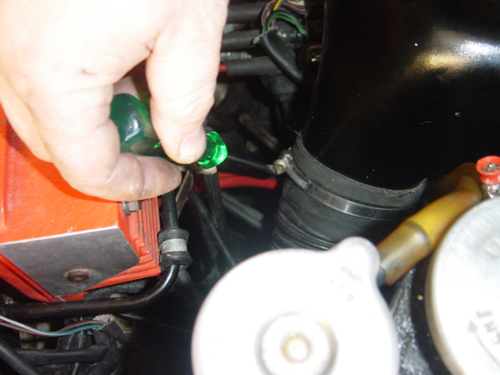

Oil

Catch Tank: High performance engines and race cars are routinely

fitted with catch tanks to collect oil mist that is produced by

pressurisation of the sump.On the Esprit there is an oil/air separator

(Green plastic thing, see below) which is supposed to trap all

the oil and feed it back to the sump.

We recommend to find a good place for your Oil catch tank before

you start cutting or disconnecting hoses. Since we don't like

drilling the Air box to fit the tank as its been suggested by

others we decided to place it a little lower (see pic below).

The catch tank was fitted by Steve Tailor from " The elan

factory" in a lower more natural position for any oil deposit

to flow through properly as gravity is important to this mod.

If

you are happy with it's resting place, disconnect the thick oil

breather hose going to the air box and extended with your choice

of hose into the catch tank if you require, ours did not need

an extension only a small step down hose to connect properly to

the tanks fitting.

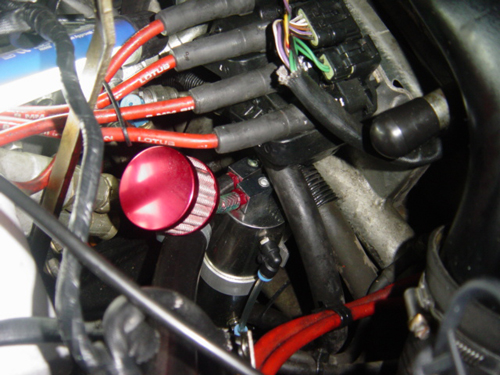

You

will need to block the fitting where the hose attached on the

air box using a plug (see pic below). We also installed a breather

filter to the oil catch tank since it must be able to breath.

Note:

This modification does may not comply with road regulation in

some countries including Australia. Your other choice to comply

is to fit the breather oil catch tank hose back into the Airbox.

This

process is illustrated in our mods page.

This process is referenced from LEW. LEW has used a different

unit than ours but you will get the idea.

If there is any interest in this Catch Tank Kit, then it can be

supplied as a package by us. e-mail

us for details.

Road

test result:

This

completes the 1 stage of the project. We road test the vehicle

with a K&N Air filter installed and the car felt and sound

so much more like a super car. You can hear the turbo and Air

box working well that's if you don't mind those kinds of sounds,

the power and power response feels like it has increase up to

20%. We can now notice wheel spin after 3000 revs, power is almost

constant during the rev range, some turbo delay is to be expected

however this should be solved on the next stage.

Dyno results: 203BHP

Note:

measuring Horse Power at the wheels. (on 4rth Gear)

On

a dyno you will always see very strange Hp-figures when you put

an Esprit on it. The main reason for this is the fact that MAT

(= mass air temp) and coolant temp will be too high on a dyno

and for that reason the ECM will retard ignition and as a next

step it will also lower max. boost. There are also some other

parameters that will have an influence especially when you do

these dyno runs. For all the above reasons the final figure on

Horse Power can differ up to 40% less from what the vehicle can

do on the road.

DYNO Graph

ECU Chip #2

STAGE

3

-

Chip # 5installation.

-

Manifold updates

- DUMP

VALVE (BOV)

- Fuel

Injector service/test

- Back

Pressure Valve

Installing

a BOV at this stage the Esprit will perform better through changing

gears by reducing turbo lag. The turbo will also spin up quicker

when back on the throttle as it will now keep spinning. This kit

will also protect your turbo from wear, by releasing pressure

which would normally stall the turbo causing increase wear and

tear.

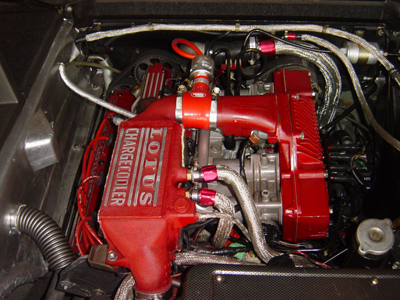

However

we have done some cosmetic work to the inlet manifold after consulting

with many experts regarding powder coating the area, however powder

coating was not recommenced for our project due to the heat transfer

characteristics the coating provides and remember we are trying

to cool the area as much as possible here, so we ended up with

the next best solution of plastic media blasting which

was done by CAR-STRIP in Melbourne. Plastic media blasting

apparently does not leave any particles which can harm the engine

and its also easy to clean with water after the process has finished.

We finished the job with a special red

VHT wrinkle paint and PPC

protective clear coating for the inlet manifold.

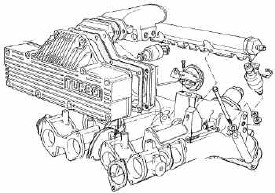

The

4-cylinder models (SE, S4, S4s & GT3) use an air/water heat

exchanger (chargecooler) to reduce the air inlet temperatures

and so increase the density of air leaving the turbocharger compressor

before it enters the intake plenum chamber. The chargecooler is

flexibly mounted to the engine, and uses flexible high temperature

hoses to connect the intake and outlet to the compressor and plenum

respectively. Air passing through the chargecooler flows past

a matrix of tubes through which water is circulated in a closed

system by an engine driven pump. Heat is transferred from the

intake charge air to the water which is pumped via alloy pipes

routed through the chassis backbone, to a chargecooler radiator

mounted ahead of both the air conditioning condenser and the engine

cooling radiator.

The

system is prone to many problems and it is vital for the optimum

performance of your car that this system is in tip top condition.

Lowering the inlet air temperature is a very safe and easy way

to increase engine performance. You gain approx. 0.5 - 1 hp for

every 1 °C you can lower the inlet air temperature.

Our

initial upgrade is to achieve a better results with the factory

assembly. Revolution Racegear provided us with a special

heatshield material for the chargecooler, this product provided

sufficient heat protection from the T3 turbo generating heat using

the stock pump. All these products worked well supporting the

heat transfer we wanted to achieve and help the engine to run

cooler.

Our

team is also working on a temperature controlled Johnson

CM30P7-1, Part Number 10-24504-03, 12V which we will test

on a later day.

*

Recommended position for the Johnson pump (no need to drill the

body. Use the solenoid screws coming through the boot panel

The

Johnson pump can be wired to the system a couple of ways showing

in our upgrades page and more importantly

this solution is also supported by Lotus Factory. However our

team will develop a temperature controlled circuit at a later

stage to improve the operation of this system even more, this

mod will help the chargecooler to run at its optimum temperature

while circulating the water as the engine requires during higher

temperatures. That way the pump will not run at full power as

per the original tests. This pump was tested at 30lts/min.

We

suggest if you ever get to this stage to also improve the internal

surface of the manifold, there is a lot of air flow lost from

the turbo to the throttle body inlets. International tests have

shown that the standard inlet system lost over 30 cfm of airflow

from turbo to the inlet ports. However with a little matching

up of the inlet manifold to the ports, gas flowing the nozzle

and plenum you could get this down to about 7-8 cfm loss. The

entry of the nozzle to the plenum is quite restrictive.

Over 5mm can be machined from the entry of the nozzle to the plenum

and all the edges can be reduced off and matched to the individual

gaskets. Thanks to Steve from "The elan factory" showing

us the way it's done. Next step is to polish the manifold internals

and cut the casket to the new shape of the manifold, this will

help to gain the air flow and complete the job right.

Fuel

Injectors Service: Both

stock primary and secondary (Bosh) injectors were tested and passed.

At this stage we will not make any upgrades to the injection system

till we complete all the dyno stages. In case of an upgrade the

only recommendation is to replace only the secondary injectors

(see stage 6) as the primary will work very well up to 350+ HP.

Stock

Secondary Injectors measured at 17ml flow, Primary Stock Injectors

should be at 36ml flow

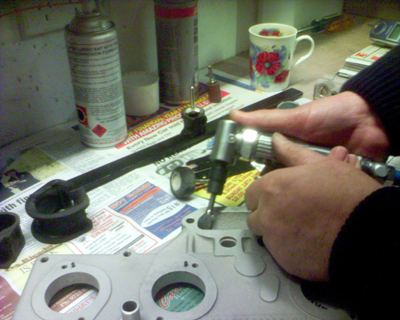

Back Pressure Valve: Since we had clear view to the inlet

manifold during this stage we were able to remove the exhaust

back pressure valve assembly attached on the manifold including

the pivot arm showing on the picture below. We also had to make

the appropriate modifications to the vacuum lines to trick the

ECU that the system is still connected.

You will also need to install a spacer at the exhaust where the

back pressure valve is located as the valve will now be closed

(Don't go anywhere before you do this) If you don't have the appropriate

exhaust spacer at the time you can wire the valve open for the

time been to hold the butterfly open or If you don't want to install

the spacer you can also take the butterfly off from the assembly

which will cause you to disconnect part of the exhaust to get

to it and remove the butterfly from the assembly. If you are able

to do this you can re install the original butterfly body back

to its original position to act as an spacer this time.

Exhaust

spacer is available from our parts list

part seen below.

This

process is illustrated on the mods page.

Road Test: The first thing we notice is all the

new sounds coming from the BOV valve and the Airbox. it's like

driving a different vehicle, this is not quite car any more and

it takes time to get used to from the stock system, forget about

turning the stereo on there is a better song at the back end.

The power is more noticeable at the top end as the boost has been

increased so plenty of pull from the 2.2ltr engine.

Dyno

results:

209 BHP

Note:

measuring Horse Power at the rear wheels. (on 4rth Gear)

On

a dyno you will always see very strange Hp-figures when you put

an Esprit on it. The main reason for this is the fact that MAT

(= mass air temp) and coolant temp will be too high on a dyno

(up to 20 degrees celcius noted in our tests.)and for that reason

the ECM may retard ignition and as a next step it will also lower

max. boost. There are also some other parameters that will have

an influence especially when you do these dyno runs. For all the

above reasons the final figure on Horse Power can differ up to

40% less from what the vehicle can do on the road.

NOTE:

This tests were focused on the performance produced by #5 ECU

ship installed in a stock engine with the original Exhaust system.

DYNO

Graph

Chip #5 results

STAGE 4

Parts

installed: (Mark I) Sports EXHAUST SYSTEM fitted with a Catalyst

testing Chip#2 and #5 with a K&N filter.

Road

Test: The car was much stronger across the rev range with

the turbo coming a little faster. The sound of this system is

perfect for those who don't want to attract to much attention.

This system is totally legal and now the car sounds as it should.

Dyno

Results: 227 BHP

ECU

Chip #2 and #5 with the Mark I sports exhaust system produced

clearly 218 and 227 BHP. See more detailed tests with many other

ECU chip configurations in our Exhaust

page

DYNO

Graph ECU

Chip #2 Vs #5

STAGE

5

Parts

Installed: ECU PROM UPGRADES Chip#6, (Mark I) Sports EXHAUST SYSTEM

fitted with a Catalyst, K&N filter.

Road

Test: This is the first time that we noticed considerable

deference in Horse Power using deferent chips. The #6 chip is

the way to go for maximum performance however it will require

some extra mods to the fuel injection as we have noticed the car

running lean across the rev range and the turbo lucking of top

end power due to its factory limitations. This was expected ....!!!

Factory

Turbo

The 1990-1993 SE and 1993-1996 S4 were fitted with a Garrett T3

with a 40 or 50 trim compressor wheel. It has a maximum flow rating

of 30 lbs/min at a pressure ratio of 2.2 (1.2 bar boost) with

58% efficiency.

The bottom line is that once you start producing a very free flowing

engine setup; air filter, ram air mod, exhaust mod, de-cat pipe

the turbo then become the weak link in the system. The turbo in

the S4 cannot flow enough air at the top end, the result is that

the inlet temperature (MAT) raises very dramatically and boost

drops away. In fact there is a condition in which increasing the

boost will actually produce lest power this is clearly demonstrated

from the graph below.

As

mention above the graph is also showing drop of power due to fuel

starvation which will be fixed on the next stage.

Dyno Results: 247 BHP Stock turbocharger

Dyno

graph ECU Chip #5 Vs #6 with a factory turbocharger.

Stage

6

Parts

Used: High Flow Turbo, high volume secondary injectors, (Mark

I) Sports EXHAUST SYSTEM fitted with a Catalyst, K&N filter,

High pressure fuel pump.

Fuel

injectors _ Secondary: Although

the two plenum secondary injectors are similar in construction

to the primary injectors they are actually high impedance (16

ohm) 190 cc/min or 18 lb/hr saturated type injectors. These injectors

operate at a fixed frequency of 128 Hz, with the quantity of fuel

delivered dependent only the pulse width sent by the ECU.

The

stock S4 ECU fuel mapping only triggers the secondary injectors

over 4800 rpm and 0.7 bar boost. We have fitted 270 cc/min (25.7

lb/hr) RC Racing high impedance injectors. If you are undertaking

major engine mods it is very important to think about the correct

fueling.

The

ECU goes into "open loop" mode above 94% throttle openings, in

open loop mode there is no feedback to the ECU from the lambda

sensor, under these conditions fueling is based on pre-stored

fuel maps in the ECU.

Our

first Dyno run with the new local made experiment turbocharger

and secondary injectors showed the engine running lean across

all the rev range. At that stage we introduced a high pressure

fuel pump to correct this issue.

<

Secondary Injectors

<

Secondary Injectors

Picture above is an image of the 2 secondary RC

injectors on the bottom compared to the standard Lotus Bosch injectors.

High

pressure fuel pump: As

shown in the previews Dyno graph at this stage the vehicle is

showing running lean at the top end. To correct this we have installed

a local supplied high pressure racing fuel pump can support engine

up to 450 HP.

The

standard S4 fuel pump is a roller vane type, high pressure electric

fuel pump mounted within the right hand fuel tank. The pump supplies

fuel at 30.5-55psi to the fuel rail. On the Sport 300 the fuel

pump was upgraded to a higher capacity pump as fuel starvation

was experienced in testing. Unfortunately the Sport 300 pump is

now obsolete and so an alternative up rated delivery compatible

in-tank pump was purchased locally.

<

High Pressure Fuel Pump.

<

High Pressure Fuel Pump.

The

removal and installation of the pump is available here.

TURBOCHARGER

UPGRADE RESULTS

After

8 months R&D and testing recommended solution on turbocharger

units available, our team has installed a ball bearing unit modified

locally to produce the minimum satisfactory results used on a

stock internals engine producing 250 HP at the wheels on the dyno.

We

noticed a better performance on the road as the Mat sensor is

running much cooler producing an estimated 20 HP more due to cooler

Mat temp.

On

the dyno the car was much stronger and delivery smoother power

in the top end.

However

we will continue testing all the solutions available in the near

future to improve the results we have achieved using our local

and overseas experts/suppliers.

Over

all including stage #6 we have managed to increase the HP power

of a stock internal engine by 40% by adding the quality parts

as shown above. We will be happy to discuss any of your upgrades

or concerns with you regarding any of the stages shown.

More info on the turbo results

More info on the turbo results

![]()